Con-API’s Operation Monitoring Research

Ensuring accuracy and efficiency through real-time construction site intelligence.

Our Operation Monitoring research focuses on the developing intelligent systems for real-time detection, online information feedback, and quality assurance of construction work. We leveraging technologies such as Building Information Modeling (BIM), deep learning solutions, digital twins, and automated computer vision systems to enhance on-site decision-making and operational consistency. Through our work, we hope to advance monitoring capacity and improve productivity in the construction industry.

Research themes:

- Real-time quality assurance and issue detection

- Digital twin–enabled inspection and feedback loops

- AI-powered construction component tracking

- Sensor and vision-based site automation

Featured Representative Works

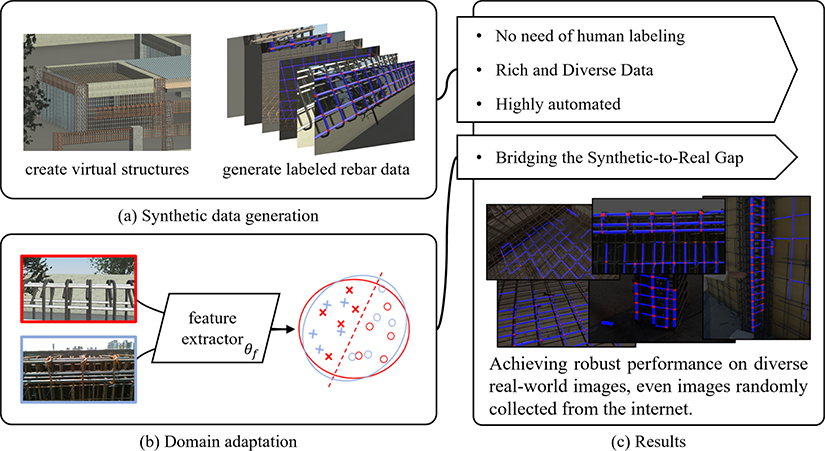

1. Huang, T. W., Chen, Y. H., Lin, J. J.*, & Chen, C. S.* (2025). Deep learning without human labeling for on-site rebar instance segmentation using synthetic BIM data and domain adaptation. Automation in Construction, 171, 105953. (SCI) ❐

The proposed method by “Huang et al. to train a deep learning model for on-site rebar instance segmentation without the need for manual labeling.”

This study tackles the research gap of manual on-site rebar inspection which is prone to human error and requires manual effort. The author introduced a novel approach to rebar instance segmentation using synthetic BIM-generated data and domain adaptation. To overcome manual dataset formulation, the authors present a label-free deep learning pipeline that leverages synthetic images generated from BIM models, forming a dataset called SORD (Synthetic On-site Rebar Dataset) with over 25,000 annotated images.

The author’s innovation enabled the model to effectively transfer learn from synthetic to real-world environments. The result is a highly generalized model that improves Average Precision (AP) performance by three times compared to models trained solely on limited real-world data. This method not only reduces labor and cost but also represents a scalable, automated quality control systems for rebar installation.

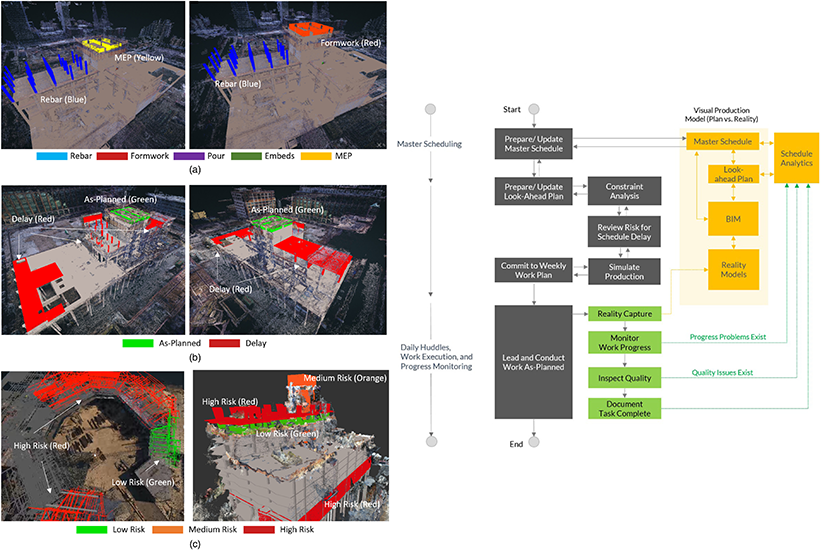

2. Lin, J. J.*, & Golparvar-Fard, M. (2021). Visual and virtual production management system for proactive project controls. Journal of Construction Engineering and Management, 147(7), 04021058. (SCI) ❐

A combination of Figures 7 & 8 from the paper: Showing the integrated visualization of a 4D production model and workflow for planning, monitoring, and controlling construction tasks, highlighting trade locations, work progress, risk levels, and data-driven coordination.

This paper presents a novel construction management system designed to tackle schedule delays and inefficient communication. By integrating visual data from the field with BIM-based 3D models, the system enables proactive delay detection, track work progresses, and identify waste across the construction site.

The proposed platform forecasts schedule risks by analyzing production trends, allowing for location-driven performance monitoring. The dashboard enables real-time collaboration across stakeholders, enhancing team-based planning, in-process quality control, and contractor coordination.

Tested on two real-world construction projects, the system led to a 30% improvement in planned work completion (PPC) and allowed project teams to finish construction four weeks ahead of schedule. The solution displays LEAN construction principles by enhancing stakeholder coordination and transforming planning into data-driven processes.

Conference Highlights

Lin, Z. J., and Lin, J. J. (2023). Automated Alignment Between Issue Tracking Items and Schedule Activities Using Rule-based and Learning Approaches. The 27th Conference on Construction Engineering and Management, July 13, Hsinchu, Taiwan (pp. 113).

Hung,D. D. and Lin, J. J. (2021). “Using Image-based Point Cloud to Improve Facility Management Process of Existing Building,” Proceedings of the 25th Symposium on Construction Engineering and Management, Paper No. 120, July 16, 2021, Taipei, Taiwan.

Project Involvement within this field

結合BIM及AI人工智慧開發建築構件安裝即時檢測技術與流程改進

Combining BIM and AI to develop real-time detection technology and process improvement for building component installation.

2023.Jan – 2024.Jan. PI

Sponsor: Architecture and Building Research Institute (ABRI)

應用建築資訊建模(BIM)、深度學習及自動辨識技術輔助建築構件精準安裝

Apply Building Information Modeling (BIM), deep learning and automatic identification technology to assist in the precise installation of building components.

2022.Jan – 2023.Jan. PI

Sponsor: Architecture and Building Research Institute (ABRI)

以深度學習與數位孿生輔助工地鋼筋與管路預埋查驗與維護

Using deep learning and digital twins to assist in the inspection and maintenance of pre-buried steel bars and pipelines on construction sites. 2021.Jun – 2023.Jun. Co-PI

Sponsor: National Science and Technology Council (NSTC)

營建工地智慧視覺監視與自動報告系統的研發

Research and development of intelligent visual monitoring and automatic reporting system for construction sites.

2020.Nov – 2024.Nov. Co-PI

Sponsor: National Science and Technology Council (NSTC)